Texas A&M University

Fracture Behaviors and Toughening Mechanisms in Polymeric Materials

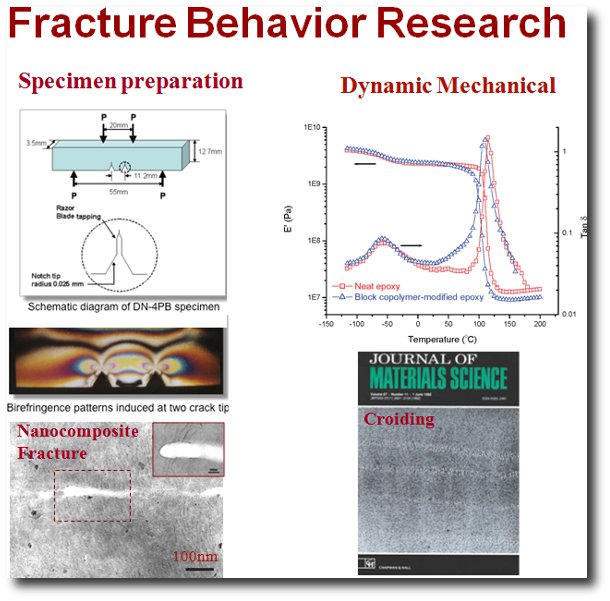

Premature facture of engineering materials usually leads to undesirable outcome and can be catastrophic. Delaying and even preventing fracture from occurring is the goal of most structural material engineers. Many polymers are inherently brittle, which may greatly limit their engineering applications. Toughening of polymers usually involves the incorporation of a second phase toughening particles, whose purpose is to improve impact resistance and damage tolerance. Elastomeric polymers are typically used to toughen engineering plastics, while rigid polymers and inorganic fillers can also be used as toughening agents.

their engineering applications. Toughening of polymers usually involves the incorporation of a second phase toughening particles, whose purpose is to improve impact resistance and damage tolerance. Elastomeric polymers are typically used to toughen engineering plastics, while rigid polymers and inorganic fillers can also be used as toughening agents.

Fracture mechanisms investigation of engineering polymers is a unique strength of our research group. We have investigated a wide variety of toughened plastics (polypropylene, polyethylene, polyketone, polystyrene, ABS, nylon, polycarbonate, biodegradable plastics, and thermosetting resins) and fundamentally study how the toughening particles (core-shell particles, ethylene-propylene rubbers, styrene-ethylene-propylene rubbers, calcium carbonate, talc, silicon dioxide, clay, zirconium phosphate nanoplatelets, and nano-sized block copolymer micelles) influence the fracture process.

|

In order to have an unambiguous understanding of the fundamentals that affect the fracture behavior of polymers, the double-notch four-point bending (DN-4PB) technique has been utilized in our group. This technique has been shown as an effective tool in probing micromechanical deformation mechanisms for plastics, blends, composites, and nanocomposites. The DN-4PB technique is one of  the most effective ways of generating a subcritical crack tip damage zone. The key toughening mechanisms, the sequence of toughening events, and their causal relationship can be identified using the DN-4PB technique, followed by a variety of microscopy techniques.

the most effective ways of generating a subcritical crack tip damage zone. The key toughening mechanisms, the sequence of toughening events, and their causal relationship can be identified using the DN-4PB technique, followed by a variety of microscopy techniques.

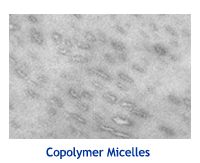

Very recently, a collaborative work with Prof. Frank Bates at Univ. ofMinnesota based on an amphiphilic block copolymer has been incorporated into epoxy as a toughener. The block copolymer self-assembles into well-dispersed nanometer scale spherical micelles with a size of about 15 nm. The nano-sized block copolymer at 5 wt% loading can significantly improve the fracture toughness without deterioration in modulus and Tg. It has been found that the nanometer size block copolymer micelles can cavitate to induce matrix shear banding, which primarily accounts for the observed remarkable toughening effect.

Other Related Fields: