Texas A&M University

Scratch Behavior of Polymers

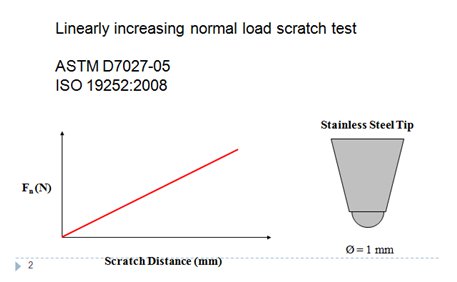

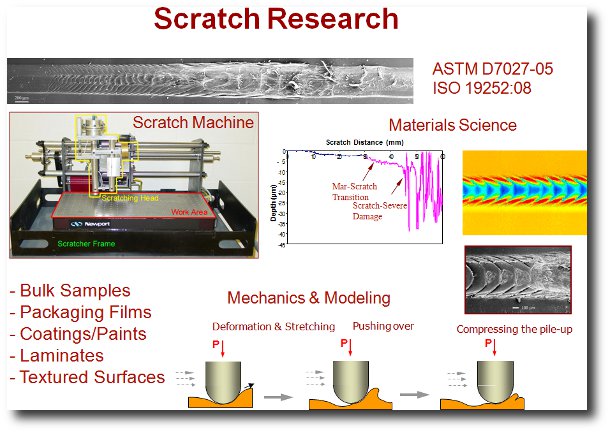

A scratch can be viewed as a sliding indentation of single-point asperity over the surface of a material, either under a constant or increasing load. The scratch behavior of polymers is an important property for various applications. Our research emphasis is to explore the mechanistic and material science explanation of scratch induced deformation in different polymeric materials. Numerical analysis such as finite element methods (FEM) is a powerful tool to provide mechanistic explanations that allow correlation with the material properties of polymers and their corresponding scratch deformation/damage mechanisms. The scratch performance of a polymer coating system was also explored with the combination of numerical simulation and experimental results. Thus, the combination of FEM simulation and experiments offers better fundamental understanding of the scratch behavior of polymers.

Fig. 1

|

Scratch visibility, often used as an easily appreciated measure of scratch resistance, is strongly influenced by surface deformation. The formation of a scratch groove and/or change in surface roughness can alter the optical condition of the original surface. Incident light will be scattered by these features until the contrast level between the scratch damaged and the undamaged background reaches the critical point of visibility. The assessment of visibility can be strongly affected by the observation angle. Laser confocal scanning profilometry is used to observe the small-scale damage features that cause scratch visibility. By using parameters based on human physiology, custom machine-vision software (ASV, Auto-detection of Scratch Visibility) has been developed to evaluate the onset of scratch visibility with pattern recognition technology.

|

Another area of concern for polymer surface damage is the so-called “mar” phenomenon. In the past, the definition for this behavior has been rather ambiguous. The only hint provided is that the damage relating to “mar” is quite subtle. Our scratch methodology shows that before the onset of scratch visibility, plastic deformation exists that has not reached the critical contrast level to be visualized by unaided human eyes. Considering the parameters used in the development of ASV, “mar” is now defined uniquely as surface damage with a contrast level below the critical level for visibility. Experiments are being designed to adapt our existing scratch methodology to address “mar” behavior of polymers based on this definition.

Other Related Fields :